- ► Contractor: General Electric, Lynn, Massachusetts.

- ► Contract value: $20,085,584 firm-fixed-price delivery order.

- ► Scope: Repair of 16 F404 engine components, totaling 275 repairs.

- ► Completion date: December 2027.

- ► Contracting activity: Naval Supply Systems Command Weapon Systems Support, Philadelphia.

US Navy Awards $20M F404 Engine Repair Contract To General Electric

The US Navy has awarded a $20,085,584 F404 engine repair contract to General Electric in Lynn, Massachusetts, to support sustainment of the F404 turbofan engine fleet.

According to a Department of Defense contract announcement, the firm-fixed-price delivery order covers the repair of 16 different F404 engine components, totaling 275 individual repairs. Work will be performed in Lynn, Massachusetts, and is expected to be completed by December 2027.

The award was issued under a previously established basic ordering agreement and does not include an option provision.

Contract Structure And Funding

The F404 engine repair contract was issued under a previously awarded basic ordering agreement, identified as N00383-22-G-TF01. The new delivery order, N00383-26-F-TF04, is structured as a firm-fixed-price arrangement, meaning the total cost is set at award.

Fiscal 2026 working capital funds from the Navy, totaling $20,085,584, were obligated at the time of award. The funds will not expire at the end of the current fiscal year.

The contracting activity is Naval Supply Systems Command Weapon Systems Support, based in Philadelphia, Pennsylvania. This office manages supply chain and sustainment support for naval aviation platforms and propulsion systems.

The requirement was pursued on a sole-source basis under the authority of 10 U.S. Code 3204(a)(1), which allows for contracting without full and open competition when only one responsible source can meet agency requirements. One offer was solicited and received.

F404 Engine Fleet Sustainment

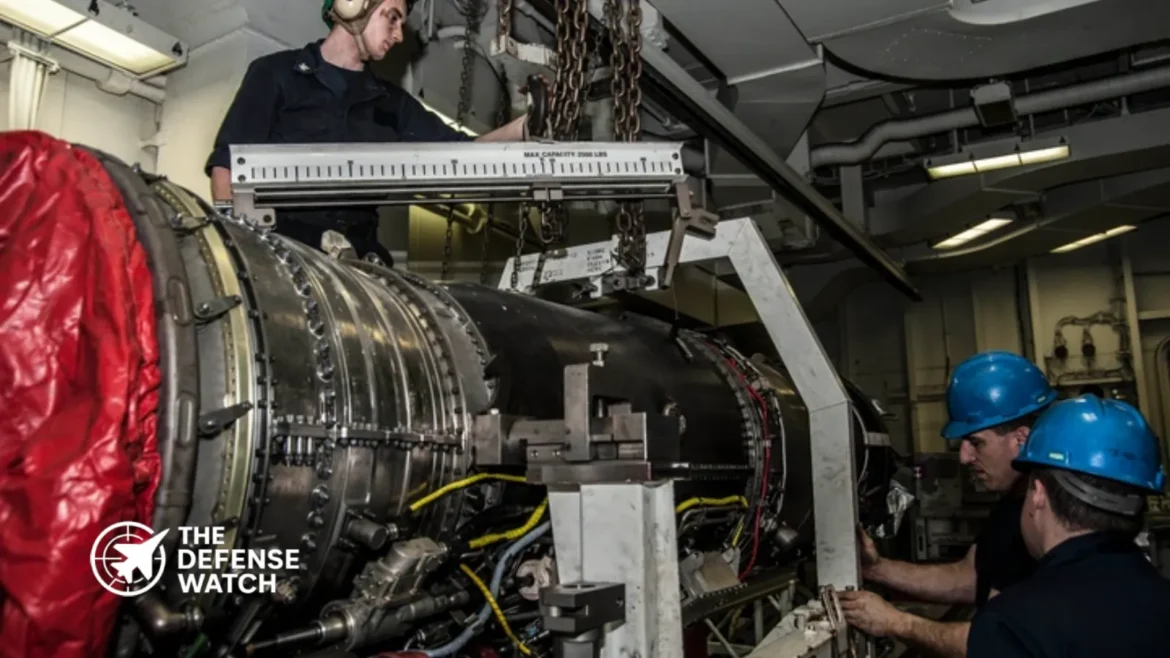

The F404 turbofan engine powers several frontline fighter aircraft, most notably the Boeing F/A-18 Hornet and variants of the Boeing F/A-18 Super Hornet. The engine is also used in international platforms such as the KAI T-50 Golden Eagle.

With hundreds of F404 engines in service globally, component repair contracts play a central role in maintaining operational readiness. Depot-level maintenance and component refurbishment extend engine life cycles, reduce replacement costs, and support fleet availability.

General Electric, headquartered in the United States, has long served as the original equipment manufacturer for the F404 series. Sustainment contracts like this one ensure continued access to technical data, proprietary parts, and certified repair processes required to meet naval aviation safety and performance standards.

Broader Context In Naval Aviation Sustainment

The award underscores the Navy’s ongoing investment in propulsion sustainment amid high operational tempo and aging aircraft inventories. While the Navy continues to modernize its carrier air wings with newer platforms, legacy F404-powered aircraft remain active across training and operational units.

Firm-fixed-price repair contracts provide cost predictability for the service while securing specialized industrial base capacity. Lynn, Massachusetts, remains a critical site for F404 engine production, overhaul, and repair activities.

As the Navy balances modernization with readiness, sustainment awards such as this F404 engine repair contract form a steady component of its aviation budget strategy.

Get real time update about this post category directly on your device, subscribe now.